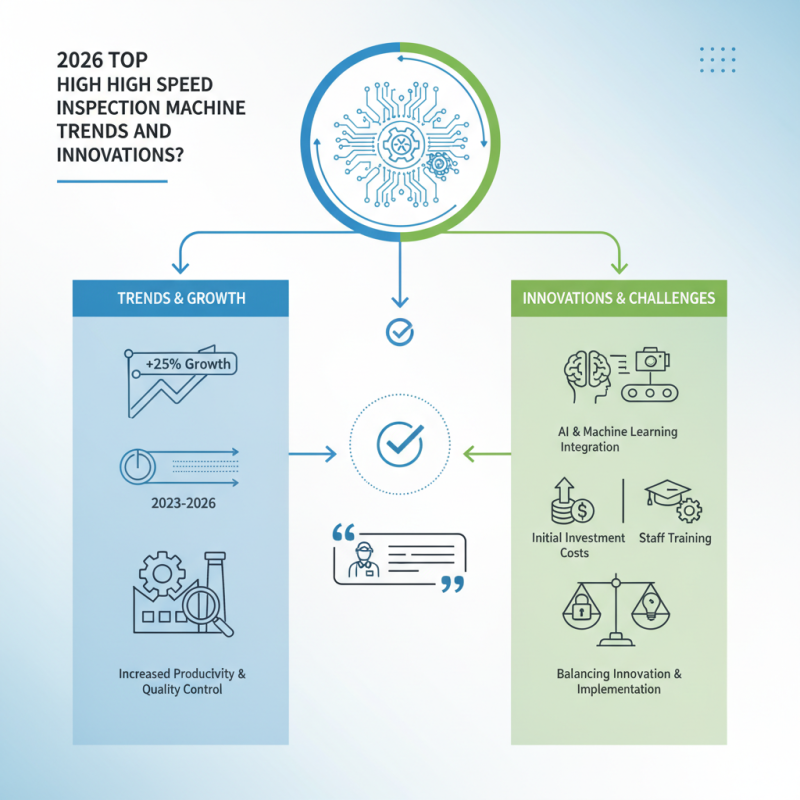

In recent years, the advancements in High Speed Inspection Machines have significantly transformed various manufacturing sectors. A report from Technavio indicates that the global market for these machines is expected to grow by over 25% from 2023 to 2026. This trend highlights the urgent need for industries to adopt innovative technologies that enhance productivity and ensure quality control.

Industry expert Dr. Emily Chen states, "The rise of High Speed Inspection Machines is not just a trend; it's a necessity for businesses aiming for efficiency." These machines offer faster processing speeds and improved accuracy, leading to reduced production costs and minimal errors. However, despite their benefits, some manufacturers struggle with integrating these technologies effectively into their operations.

As the industry evolves, innovation in High Speed Inspection Machines continues to emerge. Technologies like AI and machine learning are being incorporated to improve inspection outcomes. Still, companies must reflect on potential shortcomings, including the initial investment costs and training requirements for staff. Balancing these innovations with practical implementation remains a challenge for many organizations.

The landscape of high-speed inspection machines is evolving rapidly. In 2026, we see a major shift towards automation and AI integration. These machines are now capable of detecting defects with incredible accuracy. Speed and efficiency are crucial. Companies are investing heavily in these technologies to reduce downtime.

Tips: Always evaluate your inspection needs. Determine if high-speed is necessary for your processes.

Another notable trend is the use of data analytics. Machines collect vast amounts of data during inspections. This data can be analyzed for process improvements. Insights gained help streamline production lines and enhance quality assurance. However, not all organizations utilize this data effectively. There is often a gap between technology and its application.

Tips: Keep training your team on new technologies for maximum effectiveness. A skilled workforce is vital.

Furthermore, sustainability is becoming a focus. Companies seek machines that consume less energy and produce less waste. High-speed inspection machines now incorporate eco-friendly practices. Yet, sometimes these initiatives can lead to higher operational costs initially. Balancing cost and sustainability remains a challenge for many.

Tips: Consider long-term savings over immediate costs. Sustainable choices often pay off.

This chart displays the trend adoption rates of various innovations in high speed inspection machines for 2026. Automation leads the way with an 85% adoption rate, followed by AI integration and data analytics, indicating a strong movement towards more advanced and reliable inspection technologies.

Artificial Intelligence (AI) is transforming high-speed inspection processes. The integration of AI enhances accuracy and efficiency. Automated inspections can detect defects with precision, reducing reliance on human inspectors. AI algorithms analyze data in real-time. This leads to quicker identification of anomalies.

However, challenges exist. Not all AI systems are perfect. Some may misinterpret data, leading to false positives. This requires continuous monitoring and refinement. The learning curve for operators can also be steep. Training personnel to utilize AI effectively is crucial for success.

The future holds exciting possibilities. Improved algorithms can further enhance inspection quality. As AI technology advances, machines will become more adept at decision-making. Embracing these innovations can significantly impact production efficiency. Companies must remain open to evolving practices while addressing potential pitfalls.

The impact of automation on efficiency in inspection machines is significant. Automation reduces human error, streamlining processes. A recent report shows that automated inspection systems can improve accuracy by up to 30%. This increased precision is crucial in industries like manufacturing and pharmaceuticals, where quality is paramount.

Moreover, the speed of inspection has drastically improved. Many facilities now rely on high-speed machines that can analyze thousands of products per hour. Traditional methods simply can’t match this throughput. However, this rapid pace raises questions about oversight. As machines take on more responsibility, there is a need for constant monitoring to ensure they function correctly.

Data from various industry studies emphasize that while automation boosts productivity, it can also create gaps in workforce skills. Many workers may feel uneasy with rapidly changing technology. Companies must invest in training programs to bridge these gaps. The transition to automation is not without its challenges, and stakeholders must consider these aspects to fully realize the benefits.

In the realm of high-speed inspection machines, vision systems play a crucial role. Enhanced inspection accuracy significantly hinges on advanced imaging technologies. Recent reports indicate that the market for vision systems is projected to reach $9 billion by 2026. This surge highlights the increasing reliance on automated inspection processes across various industries. With artificial intelligence entering the field, these systems can now analyze images in real-time more effectively.

The integration of machine learning into vision systems leads to more precise defect detection. Algorithms learn from past inspection data, improving over time. However, despite these advancements, challenges remain. Some systems still struggle with complex surfaces or unpredictable lighting conditions. A study shows that around 25% of inspections still yield false positives. This reflects the need for constant improvement, as even minor inaccuracies can lead to significant operational costs.

Another trend is the miniature cameras that fit into compact spaces for inspection. These devices often operate at high speeds while maintaining picture quality. However, they can be sensitive to vibrations. Thus, maintaining stability during operation is essential for optimal performance. User feedback suggests that fine-tuning these systems requires ongoing trial and error, highlighting a continuous need for innovation in this field.

The market for high-speed inspection machines is set to grow significantly by 2026. With advancements in technology, industries require more efficient solutions. This trend reflects the need for speed and accuracy in quality control processes. Companies are expected to invest heavily in automation and innovative detection technologies. Improved inspection capabilities are essential in meeting rising production demands.

Manufacturers will increasingly adopt machine learning and AI in their inspection systems. This integration can enhance fault detection and reduce error rates. However, many companies may struggle with the transition to these advanced systems. Training staff and ensuring system compatibility can pose challenges. Despite these hurdles, the benefits of efficiency and reduced waste are compelling.

As the market evolves, sustainability will become a more prominent focus. High-speed inspection machines will not only need to be efficient but also eco-friendly. The demand for lower energy consumption and recyclable materials will reshape product design. Companies face the pressure of balancing innovation with environmental responsibility. Those who succeed will likely lead the industry into a new era of sustainable practices.

| Trend/Innovation | Projected Market Growth (%) | Key Drivers | Revenue (Million USD) |

|---|---|---|---|

| Artificial Intelligence Integration | 15% | Increased efficiency and accuracy | 500 |

| Real-time Data Analytics | 10% | Demand for proactive quality control | 400 |

| Enhanced Sensor Technology | 12% | Improved detection capabilities | 450 |

| Automated Quality Control Systems | 18% | Reduction in labor costs | 600 |

| Cloud-Based Inspection Solutions | 14% | Accessibility and ease of use | 550 |