In the evolving landscape of industrial materials, choosing the right Aluminum Wire Coating is crucial. According to a report by the International Aluminum Association, the demand for aluminum coatings has surged by over 30% in the last five years. This growth indicates a significant shift towards efficiency and durability in electrical applications.

Expert John Smith, a renowned authority in aluminum technology, emphasizes, "The right coating can enhance performance while minimizing maintenance costs." With various options available, selecting the ideal coating requires understanding specific needs. Options include polyester, epoxy, and polyethylene coatings, each offering distinct advantages.

Yet, many businesses overlook key factors. Unsuitable coatings can lead to premature failures or subpar performance. Reflecting on this, companies must consider environmental conditions, conductivity requirements, and application methods. Striking a balance between cost and quality is essential for optimal performance.

Choosing the right aluminum wire coating involves several important factors. One major consideration is the environment where the wire will be used. For instance, high humidity or salty conditions can lead to corrosion. A coating that resists these elements can prolong the wire’s lifespan significantly. Look at the specific needs of your project.

Another factor is the intended application of the wire. Heavy-duty uses may require thicker coatings to ensure durability. Conversely, lighter applications might benefit from a thinner, more flexible coating. It's essential to visualize how the coated wire will perform under stress. Pay attention to the potential need for flexibility and how it interacts with other materials.

One aspect often overlooked is the aesthetic quality. Color and finish can impact the overall design. However, choosing based solely on appearance can be misleading. Sometimes, the most appealing options may not hold up as well over time. Reflecting on the long-term implications of your choice is crucial.

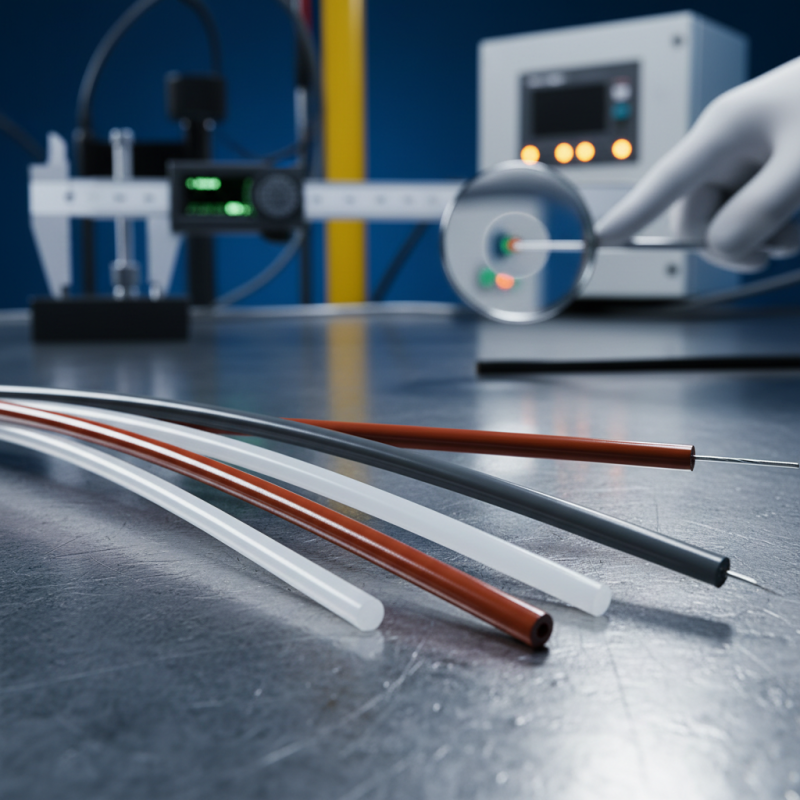

When selecting an aluminum wire coating, understanding the types available is crucial. There are several options, each with distinct characteristics suited for various applications. Common coatings include polyvinyl chloride (PVC), polyethylene, and fluoropolymer. PVC is popular for its durability and resistance to moisture. It performs well in both indoor and outdoor environments.

Polyethylene coatings are often chosen for their lightweight properties. They are less resistant to high temperatures compared to PVC. Fluoropolymer coatings, such as PTFE, offer excellent non-stick properties. However, they can be more expensive and may not be suitable for all situations. In a 2022 market analysis, it was reported that the global demand for aluminum wire coatings has increased by 15% annually, highlighting the need for informed choices.

Evaluating the environment where the wire will be used is essential. For example, PVC might deteriorate in extreme heat, while fluoropolymers can resist chemicals but may not be necessary for all applications. Understanding these nuances can prevent costly mistakes. Research indicates that installations that fail to account for the specific environment lead to significant long-term expenses. Manufacturers should prioritize a thorough assessment before deciding on a coating type.

Choosing the right aluminum wire coating involves understanding environmental conditions and their impact on durability. Factors like humidity, temperature, and exposure to chemicals play crucial roles. For instance, according to a recent industry report, environments with salt spray can reduce coating life by 50%. Therefore, assessing these conditions is vital before making a selection.

Tips: Conduct an environmental assessment. Identify the specific conditions your wire will face. This will help you choose the most appropriate coating.

Not all coatings are created equal. Some might perform well under mild conditions but fail in harsher environments. For example, a study found that coatings exposed to extreme temperatures may become brittle. Additionally, constant UV exposure can degrade certain finishes, affecting their protective capabilities.

Tips: Test different coatings. Small-scale trials can reveal how a coating will perform over time. Monitor these trials for unexpected failures or weaknesses. Understanding these nuances can lead to better long-term choices.

When selecting aluminum wire coatings, cost is a crucial factor. Different coating options can range significantly in price. For instance, a report by the American Wire Manufacturers Association indicates that polyvinyl chloride (PVC) coatings can cost around $0.15 per foot, while more advanced options like epoxy coatings can reach up to $0.40 per foot.

Durability and performance must also be considered. PVC coatings are generally less expensive but may not withstand harsh environments as effectively. Research shows that while epoxy coatings are costlier, they provide better resistance to corrosion and wear. This performance can lead to reduced maintenance costs in the long run. Yet, the initial investment is higher, which can be a barrier for some businesses.

It's important to evaluate your specific needs and budget constraints. Cutting costs by choosing cheaper coatings may lead to frequent replacements. The long-term implications of such choices should be analyzed. Cost-effectiveness is not just about initial outlays; it's also about the lifespan and reliability of the product. Balancing upfront costs and lifecycle expenses is key to making an informed decision.

| Coating Type | Durability (Years) | Corrosion Resistance | Temperature Rating (°C) | Cost per Meter ($) |

|---|---|---|---|---|

| PVC Coating | 10 | Moderate | 70 | 0.25 |

| Polyethylene Coating | 15 | High | 90 | 0.30 |

| Epoxy Coating | 20 | Very High | 100 | 0.50 |

| Polypropylene Coating | 12 | Moderate | 80 | 0.28 |

| Thermoset Coating | 25 | Very High | 120 | 0.60 |

When selecting the right aluminum wire coating, it's crucial to consider the application method. Different methods offer distinct benefits. For instance, spray coating provides even coverage. This method is often used for intricate shapes. It allows precise control over thickness. However, it can require more cleanup.

Dip coating is another popular option. This method can ensure uniform thickness all over the wire. It works well for larger batches. Yet, the setup time can be lengthy. The curing process must also be carefully monitored. It's essential to avoid drips and uneven surfaces.

Tip: Always prep the surface well before applying any coating. A clean, dry surface helps the coating adhere better.

Electrophoretic deposition is a high-tech method. It offers a smooth finish with excellent durability. However, it may require special equipment. Not everyone has access to this technology.

Tip: Test a small batch before committing to a large run. Mistakes can be costly, especially if the wrong method is chosen.

Choosing the best application method ultimately depends on your specific needs. Each has pros and cons worth considering.