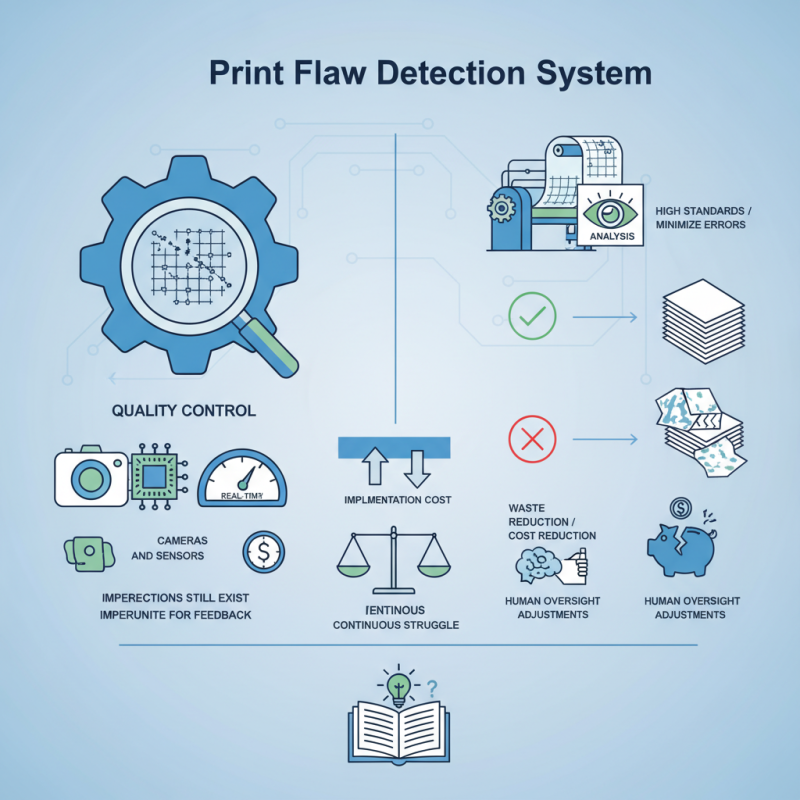

In the world of printing, quality control is paramount. A Print Flaw Detection System serves this vital purpose. It identifies defects in printed materials, ensuring high standards are maintained. This technology has become essential for printers seeking to minimize errors and waste.

Understanding how a Print Flaw Detection System operates can reveal its complexity. Cameras and sensors analyze print quality in real-time. They detect issues like color inconsistency and alignment problems. These systems offer immediate feedback, empowering operators to make quick adjustments. Yet, reliance on technology introduces challenges. Even advanced systems may miss subtle flaws. Human oversight remains critical despite automation.

Exploring the intricacies of print flaw detection uncovers its benefits and limitations. Printing companies can reduce costs, but implementation can be expensive. Balancing efficiency and quality is a continuous struggle. Ultimately, a Print Flaw Detection System enhances the printing process, but imperfections still exist. Each print run is an opportunity for reflection and improvement.

A Print Flaw Detection System is a vital tool in the printing and manufacturing industries. It focuses on identifying defects in printed materials. In an industry where quality control is crucial, such systems ensure high standards and reduce waste. Recent reports indicate that up to 3% to 5% of printed materials may contain flaws. These imperfections can lead to significant financial losses.

A Print Flaw Detection System typically employs advanced imaging technologies. It analyzes patterns, colors, and textures on the printed surface. Some systems utilize machine learning algorithms to enhance their detection capabilities. For every 1,000 products inspected, systems can miss 10–15 flawed prints. This statistic highlights a need for ongoing improvement in detection techniques. As companies invest in better technology, they should consider how effectively their systems can adapt.

These systems can sometimes struggle with complex designs. For instance, intricate graphics may lead to false negatives. Flaws that blend with the design might go unnoticed. This underscores the importance of continuous innovation and testing. Industry experts suggest regular updates to the algorithms to improve accuracy. Investing in staff training is equally vital to address these challenges.

| Parameter | Description | Importance | Detection Method |

|---|---|---|---|

| Resolution | The ability of the system to detect flaws at various sizes. | Critical for identifying small defects. | Image processing algorithms. |

| Speed | The time it takes to analyze prints for flaws. | Directly affects production efficiency. | Real-time detection systems. |

| Type of Flaws | Different kinds of defects, such as scratches, misprints, and color variations. | Helps in categorizing defects for remedial action. | Multi-spectral imaging. |

| Integration | Compatibility with existing printing machines and systems. | Essential for seamless operation. | API and protocol-based connections. |

| User Interface | The ease of use for operators. | Affects training time and error rate. | Graphical user interface (GUI). |

A Print Flaw Detection System plays a crucial role in ensuring high-quality prints. Its key components include cameras, software algorithms, and lighting systems. Cameras capture images of printed materials. They need to be precise, as even slight deviations can affect results. Software algorithms analyze these images. They detect flaws such as smudges, color inconsistencies, or misalignments.

Lighting systems also play a vital role. Proper illumination helps in identifying defects that may not be visible in standard light. They can be adjusted for different printing materials. However, achieving the right balance is often challenging. Overexposure can hide some flaws, while underexposure might miss finer details.

Despite technological advancements, imperfections can still arise. Calibration issues may lead to false positives. Environmental factors like dust can disrupt detection. The process demands constant monitoring and adjustments. Each component must work in harmony to achieve accuracy. Even though these systems are essential, they require human oversight to address overlooked errors. Maintaining quality is a continuous endeavor.

Print flaw detection systems play a crucial role in ensuring the quality of printed materials. These systems operate using advanced imaging technology and algorithms. They scan printed products for defects like smudges, misalignments, or color inconsistencies. By comparing the output against ideal standards, they identify imperfections quickly.

The scanning process is often automated. High-speed cameras capture images of the print. Software analyzes these images, looking for deviations from the expected output. This instant feedback loops back to the printing process, allowing for real-time corrections. This way, companies can reduce waste and improve overall efficiency.

Tips: Regular maintenance of detection equipment is essential. Dust and misalignment can affect accuracy. Ensure your software is updated; this keeps your system running smoothly. A system that misses flaws can compromise quality. Consider having a human quality check occasionally to catch what machines might miss. Balance between automation and human insight often leads to the best outcomes.

Implementing a Print Flaw Detection System brings numerous benefits to the manufacturing process. One key advantage is enhanced quality control. A recent industry report indicates that companies using detection systems reduce defects by up to 25%. This can lead to significant cost savings. Fewer defects mean less waste and higher customer satisfaction.

Another crucial benefit is efficiency. These systems streamline the quality assurance process. Rapid detection of flaws minimizes downtime. Employees can focus on fixing issues instead of searching for them. According to research, companies can cut inspection time by as much as 30% with the right technology.

Tip: Regularly update your detection software to improve accuracy. New algorithms can find flaws more effectively.

While print flaw detection systems enhance overall productivity, they aren't infallible. Some flaws may still slip through, especially if the system is not correctly calibrated. This highlights the need for continuous evaluation and improvement of detection metrics. Companies should not solely rely on technology; human oversight remains essential.

Tip: Conduct periodic reviews of your detection system's performance. This helps identify areas for potential improvement.

Integrating a Print Flaw Detection System, when done thoughtfully, can lead to substantial gains in both quality and efficiency.

Print flaw detection technology is essential in various industries. It helps ensure that printed materials meet quality standards. This technology is commonly used in packaging, textiles, and automotive industries. In packaging, flaws like misalignment or color mismatches can lead to faulty products. Detecting these issues early prevents waste and costly recalls.

Textile printing often faces challenges, such as inconsistent designs or faded colors. Flaw detection systems can identify these problems quickly. This allows for on-the-fly adjustments in printing processes. However, not all systems can catch every flaw. Some minor imperfections may go unnoticed, leading to potential dissatisfaction.

In the automotive industry, print flaws can affect safety labels or control panels. A small error can have significant consequences. Implementing a robust detection system is crucial, but it is not foolproof. Periodic reviews and updates of the systems are necessary. Continuous improvement helps in refining flaw detection capabilities and overall product quality.